| 23 Sep |

| 2021 |

The rope has been used since prehistoric times. It is used throughout construction, seafaring, exploration, sports, theatre, and communications. Many types of knots have been developed to fasten with rope, join ropes, and utilize rope to generate mechanical advantage. Pulleys can redirect the pulling force of a rope in another direction, multiply its lifting or pulling power, and distribute a load over multiple parts of the same rope to increase safety and decrease wear.

The ancient Egyptians were the first civilization to develop special tools to make rope. Egyptian rope dates to 4000 – 3500 BC and was generally made of water reed fibers. Other ropes in antiquity were made from fibers of date palms, flax, grass, papyrus, leather, or animal hair. The use of such ropes pulled by thousands of workers allowed the Egyptians to move the heavy stones required to build their monuments.

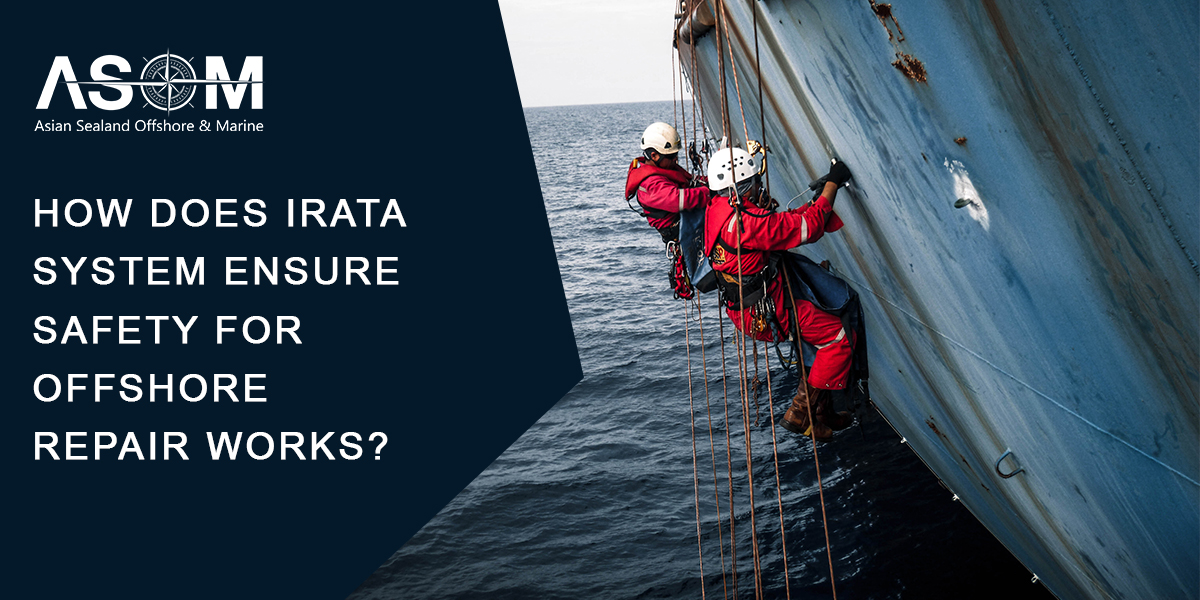

IRATA was formed in the UK in the late 1980s. It was set up to solve maintenance challenges in the offshore oil and gas industry. Its formation was the result of an initiative of several leading companies, who had begun to use industrial rope access techniques, to provide a safe working environment for the industry.

The IRATA two-rope, fail-to-safe technique developed by IRATA is used in a wide range of repair, maintenance, inspection, and access work. Rope access methodology boasts an unrivaled safety record, short set-up and dismantling time, positive environmental benefits, and removes the need for invasive access equipment or disruption to a worksite.

With the rising demand for natural energy, wind turbines are being installed around the world. Thus, Rope access workers are in demand as they will be required to work in the high element of the wind turbines. Work such as repairing the spinner requires rope access knowledge.

Legislation in health and safety and working at height are far stricter than in previous years. If a company fails to follow safety rules, it could tar its reputation. Seeking professional help from a qualified work-at-height company with a proven safety record will mitigate any potential safety risks.